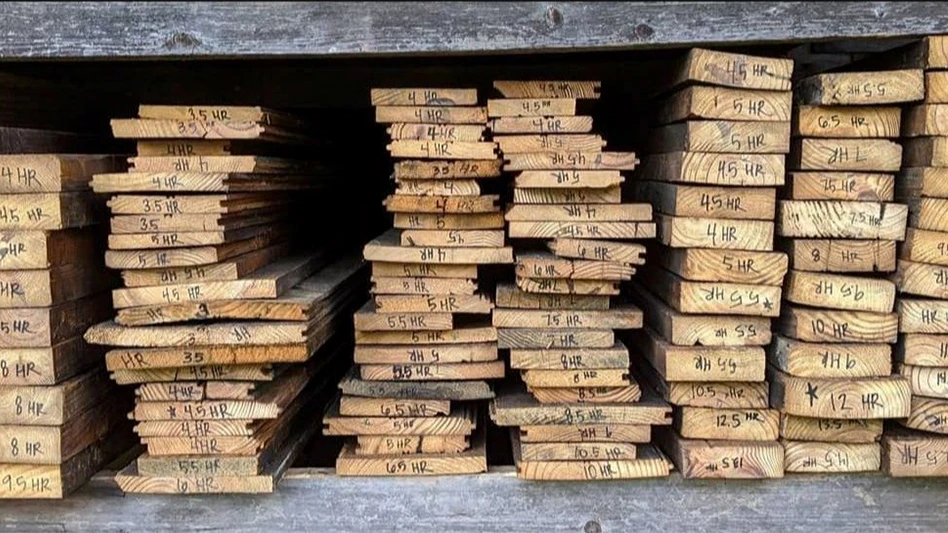

Photo courtesy of Build Reuse

The Pittsburgh-based association Build Reuse is among nearly 40 organizations that have been selected to receive U.S. Environmental Protection Agency funding aimed at reducing greenhouse gas (GHG) emissions for construction materials.

With its funding, Build Reuse will work during a five-year period with the building material reuse industry to gather data and develop Environmental Product Declarations (EPDs) for salvaged construction materials.

“An EPD provides at-a-glance information about a product’s carbon footprint,” Build Reuse says.

“The reuse industry will now be able to measure its carbon impact and show why reusing the materials we already have is a better choice for our planet and our communities,” says Shannon Goodman, president of Build Reuse and executive director of the Lifecycle Building Center in Atlanta. “Demonstrating the quantifiable value of reuse will generate additional investment to transform our reuse infrastructure so this practice can become the standard, not the anomaly."

Build Reuse, formerly known as the Building Materials Reuse Association (BMRA), says, “While construction materials and products have numerous social and economic benefits, they currently have significant environmental costs [and] the production of construction materials accounts for 15 percent of annual global GHG emissions.”

The organization says reused and salvaged materials “are generally understood to have the lowest carbon footprint among all construction materials, but a standardized approach to creating EPDs for reused and salvaged materials—akin to nutritional labels for building materials—doesn't exist.”

The EPA funding can help eliminate what Build Reuse says is the current lack of formal and critical information.

“Architects and designers are increasingly prioritizing low embodied carbon materials for projects, driven by initiatives like the Federal Buy Clean initiative, building performance rating systems, and other institutional policies and guidelines," the group says.

If salvaged timber or fixtures can carry an EPD, it will accelerate demand” for such products that can demonstrate their lower carbon footprint and make it easier for federal, state and local governments and other institutional buyers to ensure the construction projects they fund use climate-friendly products and materials,” including components harvested during a deconstruction process.

“With this EPA funding, Build Reuse will provide funding and support to material reuse operations to develop hundreds of EPDs for reused and salvaged materials," Build Reuse says. "The resulting EPD collection will allow reused and salvaged materials to be evaluated and compete against newly manufactured materials, demonstrating the role reused materials can play in boosting local economies.”

“Reclaimed construction materials play a key role in decarbonization of the built environment while providing lasting benefits for communities,” says Lindsay Baker, CEO of the Portland, Oregon-based International Living Future Institute. “The work that Build Reuse will be doing through this grant—quantifying impact and smoothing pathways to effective procurement—will help scale the adoption of reuse.”

Build Reuse's Deconstruction + Reuse Conference ‘25 will take place Aug. 4-6, 2025, at The Landmark Center in St. Paul, Minnesota.

Latest from Construction & Demolition Recycling

- US Senate backs reduced cuts to EPA

- US EPA offers brownfields-related funding

- Sky Quarry seeks crowdfunding support

- Caterpillar releases the new Cat 980 GC Wheel Loader

- NAPA leaders participate in USDOT roundtable

- Yanmar CE launches full line of compact equipment

- Metso reports increased orders after flat H1

- Block Island Recycling Management Inc. aims to promote environmental stewardship