In a city with an aging infrastructure like Chicago, buildings are constantly being torn down or remodeled. An old office building might be the next spot for a trendy new apartment complex. An old factory might make a hot new dance club. Buildings are constantly being converted and developers are eager to recycle the materials coming out of those projects.

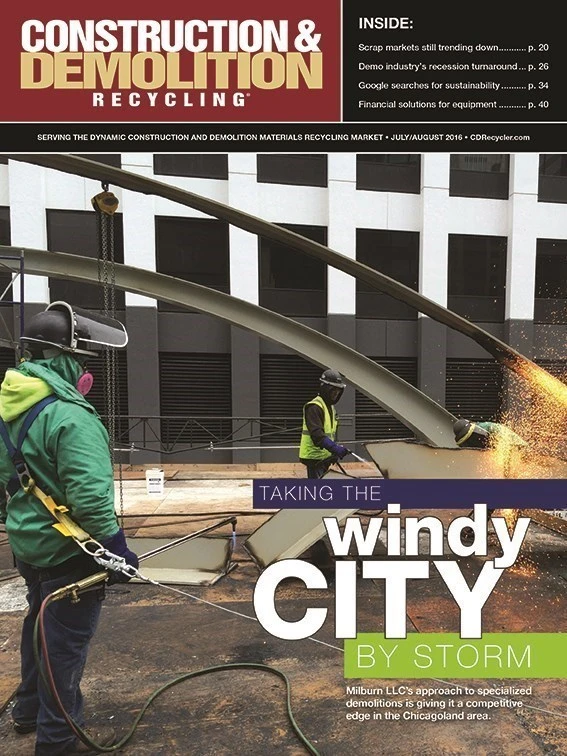

While large national demolition firms often take on the major projects, one demolition firm has made a name for itself by tackling some the smaller but more specialized work. That company is Milburn LLC and its owner, James Milburn, credits the company’s innovative use of technology and equipment—but more importantly its team of dedicated employees—for its rapid success.

“In Chicago, a lot of buildings stay, and they renovate them over and over again,” says Milburn.

Founded in February 2014, Milburn LLC has made a strong presence in the interior and selective structural demolition market in a short time. Milburn had worked in the business for about eight years before deciding to branch out and form his own company.

He says after wearing all the hats (from receptionist to estimator to delivery truck driver) he went out and hired a winning team starting with Don Collier, operations manager and Mary Ann Norton, bookkeeper. Closely following were Rich Havansek and Todd Westmoreland, project managers, and Karen Tierney, project coordinator. Today, Milburn LLC has eight full-time employees who work out of the company’s Hillside, Illinois, headquarters, and employs anywhere from 60 to 95 skilled laborers working at 10 to 15 job sites.

Milburn says, the company’s focus is not buying buildings and bidding jobs for the value of the scrap material. The recycling Milburn performs is more in helping clients achieve their recycling and landfill diversion goals, and Milburn LLC, has gotten very good at it.

SET APART

What sets Milburn LLC apart, according to Milburn, is its “use of new equipment and attachments when available as well as technology that increases our field-to-office communication methods.”

The company owns a fleet of Bobcat skid steers and Brokk remote-controlled demolition robots for its projects. Using these tools, the company removes ferrous and nonferrous metals, concrete, and many interior building components like ceiling tiles, carpet and flooring for recycling.

“Our favorite projects are jobs that combine use of skid steers and Brokk’s for structural slab and wall openings in addition to full interior strip-outs,” Milburn says.

He explains in Chicago, these projects occur when developers take old buildings and convert them to different uses. Milburn LLC recently completed one such job where a 1920s office building was being converted into a hotel. Among the tasks of the job were a full interior gut, structural deck removal, stair removal, exterior wall removal, shoring and sawcutting.

Another recent example of the company’s work was the University of Chicago’s Laboratory for Astrophysics and Space Research (LASR). Milburn LLC performed full interior removal and coordination of asbestos abatement. This was followed by creating structural wall openings; slab openings for new stairs and a two-story atrium; and the full removal of a limestone façade and curtainwall system. Most of the materials from these jobs, much to the project owners’ delight, is recycled.

“In our industry there is a strong need to recycle not only for financial reasons, but to show our owners/buyers of demolition services that we are doing our best to do the right thing,” says Milburn.

The company contracts with third-party partners for hauling and sorting services to divert approximately 90 percent of the materials it recovers from projects, according to Milburn. In 2015, that amounted to 10,000 tons of materials sent out for recycling. Ups and downs in the real estate and scrap market may not affect Milburn LLC as much as some demolition firms, but Milburn says scrap income offsets some of the hauling costs.

Despite the many means and methods used in the demolition industry for decades, Milburn says the company has the ability to find unique ways to use equipment that “other people aren’t used to.” He says the company strives to stay on the cutting edge of new equipment and methods.

Milburn also attributes good communication to the company’s success. Workers in the field use mobile devices to stay in constant communication with the office. Beyond technology, key to the good communication, he says, is the mutual respect employees have for one another and the clients they serve.

“We treat our employees and clients with the highest level of respect. It is our priority to make sure both employees and clients want to work with us,” says Milburn.

REWARDING CAREER

Milburn grew up in Oak Park, Illinois, a suburb of Chicago. He attended Purdue University where he studied Building Construction Management (BCM). It was there at the West Lafayette, Indiana-based school where he was first introduced to the demolition industry and became an active student member of the National Demolition Association (NDA), the Washington-based association representing the industry.

Milburn still goes back to Purdue to give guest lectures to students. He says his ties with NDA and Purdue has helped him create relationships with the industry across the country. His former classmates are even hiring him to do work.

Milburn says he initially studied demolition because there weren’t as many students going into the field and thought it might give him a better shot at a job. He says he quickly realized he made the right choice.

“Once I started working in it, I just loved it,” he says. “Challenging projects, long hours, constant emailing and phone calls make it a mentally difficult business, but there is no better satisfaction than getting an open and honest ‘thank you’ from the client that hired us. Providing a safe and profitable service that clients can depend on is the best reward.”

Explore the July 2016 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Turkey neglects US scrap in favor of Russian shipments

- Alterra, Eco Materials open soil remediation facility in PA

- Steelmakers’ Q1 results largely profitable

- LS3600TX Low Speed Shredder enables efficient recycling

- Vermeer Recycling and Forestry specialists help simplify equipment selection

- Ritter Company discovers more business opportunities with Vermeer

- Dirt perfect: YouTuber embraces Demco Side Dump

- Montabert Multiprocessors: Power, precision, performance