Construction and demolition (C&D) industry professionals always consider safety in their work, but two incidents in Ohio in recent weeks have brought the importance of safety to the forefront.

Though tangential to the C&D fields, Atlanta-based Norfolk Southern Corp.’s train derailment in East Palestine, Ohio, and the fatal explosion at bronze alloys ingot maker I. Schumann & Co. in Oakwood Village, Ohio, this February are stark reminders of the hazards inherent in working with dangerous chemicals and molten metals.

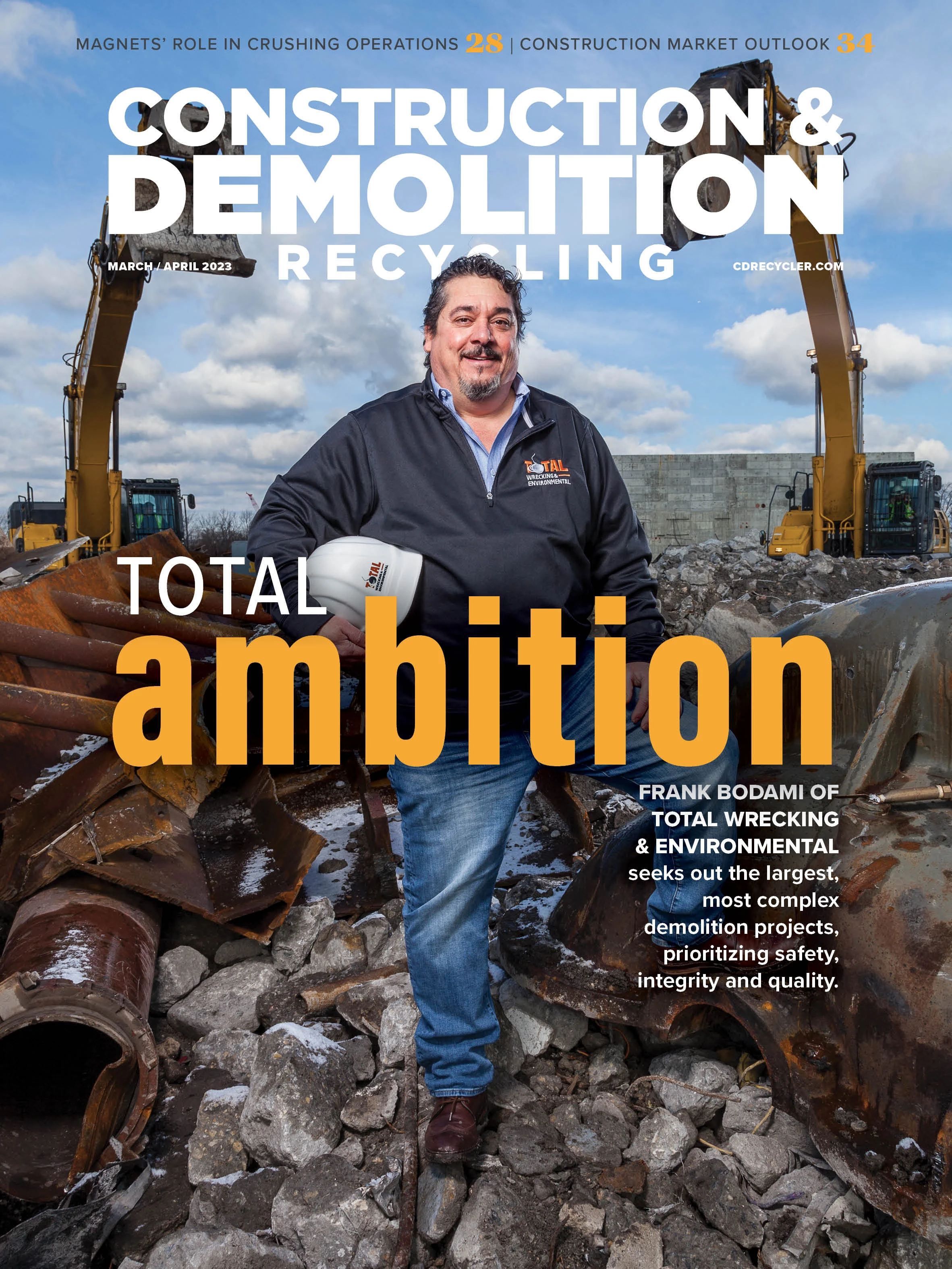

Our cover story this month, “Total ambition,” highlights the role safety must play in complex projects. Frank Bodami, co-owner of Tonawanda, New York-based Total Wrecking & Environmental, likes to take on challenging projects but always places safety at the center of his planning and operations. As a past board member of the Washington-based National Demolition Association, he led committees focusing on safety and advised the Occupational Safety and Health Administration on regulations. His interest in the environmental side of the business grew out of his experience helping with the cleanup of the Love Canal disaster in Niagara Falls, New York. Since then, Bodami has become an industry leader in safety on demolition sites and in environmental work.

Of course, balancing safety with efficiency is a perennial challenge, and we are providing our own balance in that regard in this edition.

A great deal of time can be gained for administrators with the use of dedicated software for tracking expenses and developing bids for demolition projects. Sessler Cos., Waterloo, New York, shares its experience in the article, “Connecting the dots,” with two programs from Portsmouth, New Hampshire-based B2W Software Inc.

Sessler Cos. co-owner LaVerne Sessler says using dedicated software centralizes data on past projects and creates a standardized template for bidding. On the operational side, tracking time sheets is easier because those details come in via the software with half an hour of time invested by a site supervisor rather than “200 time sheets coming in every week,” Sessler says.

Efficiency also is a focus at Champion Waste & Recycling Services, Dallas, which shares its experience using material handlers made by Germany-based Sennebogen GmbH at its C&D recycling facility in Celina, Texas, in our article titled, “Branching out.” Compared with excavators, Champion Vice President Paul Kuhar says the material handlers are precision tools that help operators search for and remove material quickly. Because Champion’s material handlers are on wheels, they also travel around the company’s paved C&D facility more quickly and safely, increasing the site’s operational flexibility and efficiency.

Still, each C&D operation is unique, and Kuhar advises curious C&D processors to try a material handler to see how it works for them.

Explore the March April 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Ferrous traders see price stability continuing

- LRS diverts 330,000 tons of recyclable material in 2024

- Elevating industry standards

- Takeuchi adds dealer locations in central US

- Tariffs target steel exporters Brazil, Canada and South Korea

- Toyota-Tsusho completes acquisition of Radius Recycling

- Motion opens new branch in Quebec

- Terex M515 trommel designed for rip rap production