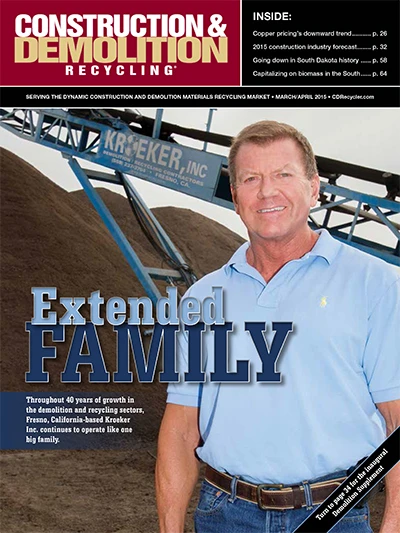

Fresno, California-based demolition and recycling firm Kroeker Inc. understands the importance of family. The family-owned company, which bears the same last name as its owners, thinks of its employees—related or otherwise—like family, according to Jeff Kroeker. His parents, Joyce and Ed Kroeker started the business in the 1970s.

Fresno, California-based demolition and recycling firm Kroeker Inc. understands the importance of family. The family-owned company, which bears the same last name as its owners, thinks of its employees—related or otherwise—like family, according to Jeff Kroeker. His parents, Joyce and Ed Kroeker started the business in the 1970s.

At that time Jeff says the company was in the business of clearing and grading properties for residential and commercial builders and developers in California’s Central Valley. But over the years, the company has evolved. Kroeker has become more focused on concrete sawcutting, demolition, and the recycling of asphalt, concrete and mixed construction and demolition (C&D) debris.

Despite the company’s tremendous growth over the last 40 years, the company’s owners have never forgotten what it means to have a company with employees that represent the family name.

“They are an extension of us,” explains Jeff, who serves as secretary/treasurer for the firm. “They are our representatives out in the field. We treat them like family, and they treat us like family.”

At 128 employees at last count, Jeff admits it has gotten more difficult to get to know everyone as the company has gotten bigger, but knowing the workers is still a priority. “You just help them out. You are there for them, and they are there for us. All hours of the night or seven days a week, we take care of each other’s needs,” he says.

Jeff began working in the family business when he was still in high school about 30 years ago. He says he has done just about every job imaginable at the company over the years from mechanic to welder/fabricator, driver, estimator and equipment operator, giving him a true understanding of the work his employees do.

“I’ve walked in the shoes of the men and women (only a few of the women’s shoes) who are currently representing us in the office and the field,” he says. “I have a real appreciation for all of them.”

Recycling pioneers

Kroeker operates a C&D recycling facility in Fresno that includes concrete and asphalt recycling. The company also has several remote sites that accept concrete and asphalt for recycling.

“The primary focus of our portable crushers is to produce a ¾-inch Class II baserock material meeting Caltrans specifications that can be used in many different applications,” Jeff says.

Ongoing infrastructure projects in central and northern California requiring large amounts of subgrade/baserock material have created a high demand for recycled aggregates and prices that have held steady, according to Jeff. Additionally, the company produces several sizes of wood chips at its C&D facility, which go toward other uses than boiler fuel. “As long as the end product is clean and consistent, we have always had a steady market for the products,” he says.

Ongoing infrastructure projects in central and northern California requiring large amounts of subgrade/baserock material have created a high demand for recycled aggregates and prices that have held steady, according to Jeff. Additionally, the company produces several sizes of wood chips at its C&D facility, which go toward other uses than boiler fuel. “As long as the end product is clean and consistent, we have always had a steady market for the products,” he says.

Jeff says the company began recycling its C&D debris in 1995, “long before any recycling goals, percentages or requirements were even talked about.” He remembers being told by a local contractor at the time that “pioneering is expensive.” The company tried several methods for sorting and recycling C&D debris, but that was only part of the puzzle. “We had to find end markets for the products, which at that time were very limited,” he says. “The quality of the product had to be good and it had to be consistently good or your buyer would go back to buying new [virgin] products.”

Another difficulty facing C&D recyclers in the Central Valley is tipping fees at landfills, which are much lower than the cost of recycling. “Without mandates or specific laws requiring the recycling of C&D debris, a lot of the debris bypasses the recycler and is buried,” says Jeff, adding that more legislative work needs to be done to promote C&D recycling.

Jeff describes Kroeker as a multifaceted company with operations that complement one another and ultimately produce a material that can be recycled. The company performs demolitions throughout California, New Mexico, Nevada and Arizona, all of which generate recyclable material.

|

Transition period Jeff Kroeker of Fresno, California-based demolition and recycling firm Kroeker Inc., has taken his decades of experience in demolition and recycling in the western U.S. to the national level through his involvement with the National Demolition Association (NDA). Jeff has served as president of the association since 2013 working with what he describes as “a very forward-thinking, aggressive board of directors.” In March, Kroeker will turn over the reins of NDA president to Peter Banks of CEI Boston LLC, Norfolk, Massachusetts. Kroeker will serve a two-year term as past president where he says he will help Banks in his new role, just as Banks has helped him. “Peter has become a great friend and has certainly earned the position,” notes Kroeker. Kroeker says he has developed many friendships with NDA members across the country and has worked with members of the National Federation of Demolition Contractors (NFDC) in the U.K. and the European Demolition Association (EDA), based in Brussels. “One thing that stands out about the NDA’s relationship with the NFDC and the EDA is their willingness and openness about sharing and allowing us complete access to their safety training programs,” Kroeker remarks. “All three associations have a goal: provide safe work practice materials to everyone involved in the demolition process.” Kroeker adds that safety issues continue to plague the demolition industry and with proper training and planning injuries can be avoided. “This is the National Demolition Association’s main focus, providing our members with the educational tools to properly train your workforce and how to plan and operate a safe work site,” he says. With Kroeker’s leadership and the leadership of the board of directors, the association transitioned its management from Doylestown, Pennsylvania, to a new management team within the association management firm Smith Bucklin in the District of Columbia in October 2014. “In the short time since the transition, we have already experienced some great positives in moving the NDA to the next level of performance and recognition,” says Kroeker. “It is a move that is sure to benefit our members.” More insights from Kroeker and newly appointed NDA Executive Director Cheryl Caulfield can be found in an interview with them on page S8 of this issue’s Demolition Supplement. |

“We perform a substantial amount of concrete cutting and core drilling on our own projects and service work for outside customers that often lead to the breaking down and removal of the material and ultimately generating a recyclable material,” explains Jeff. The roll-off services the company provides to customers and uses on its own projects also contributes to recycling volumes. Heavy demolitions and interior demolitions the company performs provide another material stream for the company. About 70 percent of the inbound material Kroeker receives for recycling at the C&D facility and crushing plants are from its own jobs. The company recycles an average of 1 million tons of material per year from the material it generates combined with that from customers.

“The largest portion of the recycled materials we produce comes from the recycling of concrete and asphalt,” notes Jeff. “We specialize in this type of recycling due to the availability of the feedstock and the consistency of the end market.”

Equipment varies from one job site to another, but Jeff says the company has used everything from a wire saw to a high-reach excavator and most pieces in between. Kroeker’s 330 size excavators get the most use because, according to Jeff, they are easy to move and can handle a wide variety of attachments.

“We like to work on multipiece projects with large concrete and an aggressive schedule where we are able to utilize our manpower and resources,” says Jeff. “A bonus would be to recycle the concrete and asphalt on site.”

The company uses jaw and impact crushers with a closed-circuit screening process to produce its popular ¾-inch base material. To produce wood chips, the company uses a 7600 Wood Hog horizontal grinder from Morbark, Winn, Michigan.

Tackling the issues

Jeff sees many issues facing recyclers and demolition contractors. Issues that affect one group also affects the other and Kroeker is involved with both sides of the equation as a generator and processor. Two years ago, Jeff was appointed president of the National Demolition Association (NDA), based in the District of Columbia. He is now nearing the end of his term. In that role, Jeff hears concerns from members from across the U.S.

One area of concern surrounds environmental laws dictating the removal of asbestos-containing material (ACM). “As a demolition contractor and C&D recycler, it concerns me that there are ‘non-regulated’ or ‘exempt’ buildings where no ACM removal is required prior to demolition, creating worker protection issues and thus eliminating the recycling of the building debris,” says Jeff.

He also notes discrepancies with agencies as to how much abatement needs to take place to comply with the California Division of Occupational Safety and Health (Cal/OSHA) and the National Emission Standards for Hazardous Air Pollutants (NESHAP).

Jeff says the solution is black and white: Without proof of removing 100 percent of the ACM, you should not be able to obtain a demolition permit. “We are not in the abatement business, but what we do have is an opportunity to provide the workers within our industry and the general public safe work practices,” Jeff says.

To address these issues as an industry, the NDA, under the direction of John Adamo, chairman of the association’s environmental committee, sent a letter to the U.S. Environmental Protection Agency with its concerns.

“We are still waiting for a response but as part of [the NDA’s] new management package, our government affairs representative is following up with a task force made up of the NDA board of directors to develop a national policy for the NDA on how to address this and other issues facing the demolition and recycling industry.” (See the sidebar “Transition period” on page 22 for more about Jeff’s involvement with the NDA and its new management.)

Jeff says he gets satisfaction from being part of the family business and the greater demolition industry family he has gained from his NDA involvement. “I enjoy seeing the growth of myself and those around me, the satisfaction of knowing the job was done correctly while always thinking about how you could have improved upon the efficiencies and performance of the last job,” he says.

And when it comes to customers, similar to the way Kroeker treats its employees, Jeff tries to put himself in their shoes. “We think about how we would want to be treated and how we would like the job to look if we were the customer paying the bill,” he explains, adding, “Without a high regard for safety and a good record of safe work practices, you will not last long in this business.”

The author is managing editor of Construction & Demolition Recycling and can be reached at ksmith@gie.net.

Explore the March 2015 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- SRS says recycling initiatives reduce costs, boost efficiency

- Tomra X-Tract model targets wood sorting

- BIR World Recycling Convention 2025: Recycled steel usage stalls in 2024

- Minnesota awards $1M in waste reduction grants

- McCloskey dealer expands its territory in the Caribbean region

- Architectural billings remain subdued

- White House signals approval of Nippon Steel-US Steel merger

- LiuGong debuts equipment at WasteExpo 2025